Materials Purchase Cycle – EXPLAINED

The materials purchase cycle, or procurement cycle, is a critical aspect of any business that deals with physical goods and products. It involves a series of steps and processes that ensure a steady and cost-effective supply of raw materials, components, and finished goods to a company. An efficient and well-managed materials purchase cycle can have a significant impact on a company’s bottom line and overall success. This article will delve into the details of each stage of the materials purchase cycle, exploring strategies and best practices for optimizing procurement processes.

Understanding the Materials Purchase Cycle:

The materials purchase cycle can be broadly divided into several interconnected stages, each with its own set of objectives and challenges. Here is a step-by-step breakdown of the cycle:

Identifying Needs and Requisitioning:

The first step in the cycle is identifying the need for materials or goods. This typically arises from production or operational requirements. For example, a manufacturing company may need to replenish raw materials for production, or a retail business may need to restock inventory for sales.

During this stage, clear and accurate communication is essential. The relevant departments must specify the type, quantity, quality, and timeline for the required materials.

A requisition form or purchase request is usually generated, detailing the needs and justifying the purchase. This form serves as the basis for the entire procurement process.

Specifying Requirements and Sourcing:

Once the requisition is approved, the procurement team specifies the exact requirements, including technical specifications, quality standards, and delivery expectations.

This stage involves thorough research and analysis to identify potential suppliers or vendors who can meet these requirements.

Sourcing involves evaluating supplier capabilities, reputation, reliability, and pricing. It may also include negotiating contracts, setting up supply agreements, and establishing long-term relationships with preferred suppliers.

Placing Purchase Orders (POs):

After finalizing the supplier and agreeing on terms, a formal purchase order is issued. This document serves as a legally binding agreement between the buyer and the supplier.

The PO typically includes details such as the specific goods or materials being ordered, quantities, agreed-upon prices, delivery dates and locations, and any special instructions or requirements.

In some cases, a blanket purchase order may be issued, which authorizes multiple deliveries or purchases over a specified period, often with pre-negotiated terms.

Supplier Delivery and Inspection:

Upon receiving the purchase order, the supplier arranges for the delivery of goods or materials to the specified location(s).

This stage involves careful logistics management to ensure timely delivery and proper handling of the goods during transportation.

Multiplier Effect

As the goods arrive, they undergo a thorough inspection to verify that they meet the specified quality and quantity standards. This process may include checking for damage, defects, or discrepancies between the ordered and delivered goods.

Inspection is a critical step to ensure that the buyer receives what was agreed upon and to prevent issues further down the line, such as production delays or customer complaints.

Invoicing and Payment:

After the goods have been delivered and accepted, the supplier generates an invoice, which is a request for payment. The invoice should match the details of the original purchase order.

The buyer’s accounts payable team then processes the invoice, ensuring it is accurate and complete, before initiating the payment process.

Payment terms and conditions are typically pre-agreed upon and outlined in the contract or purchase order. These terms may include payment due dates, methods of payment (e.g., cheque, bank transfer), and any applicable discounts or penalties for early or late payments.

Three-Way Matching and Reconciliation:

This stage involves matching and reconciling three key documents: the original purchase requisition, the purchase order, and the supplier’s invoice.

By comparing these documents, the procurement and finance teams can ensure that the correct goods were ordered and received, and that the pricing and payment terms are consistent.

Three-way matching helps to identify and resolve any discrepancies, errors, or potential fraud, ensuring accurate financial records and inventory management.

Inventory Management and Stock Control:

Once the goods are received and accepted, they become part of the buyer’s inventory or stock. Effective inventory management is crucial to ensure optimal levels of stock are maintained.

This includes monitoring stock levels, tracking usage or consumption rates, and forecasting future needs to inform the next cycle of purchasing.

Proper inventory management helps to avoid stockouts or excess inventory, both of which can impact a company’s operations and profitability.

Performance Evaluation and Supplier Relationship Management:

The final stage of the materials purchase cycle involves evaluating the performance of both the suppliers and the internal procurement processes.

This includes assessing the quality and timeliness of deliveries, resolving any issues or disputes, and obtaining feedback from stakeholders.

Supplier relationship management focuses on building and maintaining positive, long-term relationships with key suppliers. This may involve regular reviews, collaborative problem-solving, and exploring opportunities for mutual growth and improvement.

Strategies for Optimizing the Materials Purchase Cycle:

Each stage of the materials purchase cycle presents opportunities for improvement and optimization. Here are some strategies and best practices to enhance the efficiency and effectiveness of the procurement process:

Standardize and Streamline Processes:

Develop clear and consistent procedures for each stage of the cycle. Standardization ensures that everyone involved understands their roles and responsibilities, reducing confusion and errors. Streamlining processes can also help to identify and eliminate bottlenecks or redundant steps, improving overall efficiency.

Implement Technology and Automation:

Utilize dedicated procurement software or enterprise resource planning (ERP) systems to automate and integrate various stages of the cycle. Technology can help with inventory management, purchase order processing, supplier relationship management, and data analysis. Electronic data interchange (EDI) can facilitate the exchange of documents (e.g., POs, invoices) between buyers and suppliers, reducing manual effort and errors.

Foster Collaboration and Communication:

Encourage open and frequent communication between the procurement team, suppliers, and internal stakeholders (production, finance, etc.). Regular meetings, clear documentation, and a shared understanding of goals can help to prevent issues and ensure a smooth flow of goods and information.

Practice Strategic Sourcing:

Instead of treating each purchase as a one-time transaction, adopt a strategic approach to sourcing. This involves evaluating suppliers based on a range of criteria, including quality, reliability, sustainability, and long-term cost savings. Developing strategic relationships with a select group of preferred suppliers can lead to better pricing, priority service, and improved overall value.

Optimize Inventory Management:

Implement just-in-time (JIT) inventory management techniques to minimize excess stock and reduce carrying costs. This may involve forecasting demand more accurately, streamlining production processes, and working closely with suppliers to ensure timely deliveries. For slower-moving or less critical items, consider using the economic order quantity (EOQ) model to determine optimal order quantities and minimize total inventory costs.

Negotiate Favorable Payment Terms:

Work with suppliers to negotiate payment terms that align with your cash flow patterns and financial goals. For example, you may be able to obtain early payment discounts or extend payment due dates to better manage your cash outflow. Clear and timely communication about payment expectations and performance is essential for maintaining positive supplier relationships.

Regularly Review and Evaluate Suppliers:

Establish a robust supplier evaluation process that goes beyond initial sourcing. Regular reviews can help identify suppliers who consistently meet or exceed expectations and those who may require performance improvement. This process should consider not only price but also quality, delivery performance, responsiveness to issues, and overall reliability.

Embrace Data-Driven Decision-Making:

Leverage data analytics to make informed decisions at every stage of the materials purchase cycle. Analyze past purchase patterns, supplier performance, market trends, and other relevant data points. This analytical approach can help optimize inventory levels, identify cost-saving opportunities, and support strategic sourcing decisions.

Mitigate Risks and Ensure Business Continuity:

Identify and assess potential risks in the supply chain, such as supplier dependency, geographic concentration, or political instability. Develop contingency plans and alternative sourcing strategies to ensure a steady supply of materials. Regularly review and update business continuity plans to minimize disruptions and maintain operations during unforeseen events.

Prioritize Sustainability and Social Responsibility:

Consider environmental and social factors in your procurement decisions. Evaluate suppliers’ sustainability practices, including their use of natural resources, waste management, and ethical labor standards. By prioritizing sustainable and socially responsible sourcing, you can contribute to your organization’s environmental and social goals while also enhancing your brand reputation.

Benefits of an Efficient Materials Purchase Cycle:

An efficient and well-managed materials purchase cycle offers numerous benefits to a business, including:

Cost Savings:

Optimizing the procurement process can lead to significant cost savings. By streamlining processes, negotiating favorable terms, and reducing waste, businesses can lower their overall procurement costs. Efficient inventory management also helps to avoid unnecessary carrying costs and minimizes the risk of excess inventory becoming obsolete.

Improved Cash Flow Management:

Effective materials purchase cycle management can positively impact cash flow. By negotiating extended payment terms or taking advantage of early payment discounts, businesses can better manage their cash outflow. Additionally, accurate forecasting and just-in-time inventory management ensure that cash is not tied up in excess inventory, improving liquidity.

Enhanced Production Efficiency:

A steady and reliable supply of raw materials and components is essential for maintaining efficient production operations. By optimizing the materials purchase cycle, businesses can avoid stockouts and disruptions to production schedules. This, in turn, improves overall equipment effectiveness (OEE), reduces waste, and enhances productivity.

Better Supplier Relationships:

Developing strategic and long-term relationships with suppliers can lead to a range of benefits. Preferred suppliers may be more willing to offer favorable pricing, priority service, and collaborative problem-solving. Regular supplier evaluations and performance reviews help to identify areas for improvement and ensure that both parties are meeting their obligations.

Risk Mitigation:

A well-managed materials purchase cycle helps to identify and mitigate risks in the supply chain. By diversifying the supplier base, monitoring supplier performance, and having contingency plans in place, businesses can reduce their exposure to supply disruptions. Effective risk management ensures business continuity and minimizes the impact of unforeseen events.

Improved Customer Satisfaction:

Ultimately, an efficient materials purchase cycle contributes to improved customer satisfaction. By ensuring a consistent supply of high-quality goods, businesses can meet customer demands and deliver products on time. This helps to build customer loyalty, enhance brand reputation, and drive long-term growth.

Key Challenges and How to Overcome Them:

While optimizing the materials purchase cycle offers significant advantages, it is not without its challenges. Here are some common challenges and strategies to overcome them:

Lack of Internal Alignment:

Problem: Misalignment between the procurement team and other internal departments, such as production, finance, or sales, can lead to conflicting goals and priorities.

Solution:

Foster cross-functional collaboration and communication. Hold regular meetings to align goals, share forecasts, and discuss potential issues. Ensure that everyone understands the impact of their decisions on the overall business.

Limited Supplier Base:

Problem:

Relying on a limited number of suppliers can create dependency and limit negotiating power.

Solution:

Regularly review and expand your supplier base. Source alternative suppliers and develop backup options for critical materials. Diversifying your supplier base reduces risks and provides more opportunities for cost savings and innovation.

Manual and Disconnected Processes:

Problem:

Relying on manual processes and paper-based documentation can lead to errors, delays, and a lack of visibility.

Solution:

Invest in technology and automation. Implement dedicated procurement software or ERP systems to streamline and integrate processes. Electronic data interchange (EDI) can facilitate the exchange of documents and improve data accuracy.

Inaccurate Forecasting:

Problem:

Inaccurate demand forecasting can lead to stockouts or excess inventory, impacting production and cash flow.

Solution:

Improve forecasting accuracy by analyzing historical data, market trends, and customer behavior. Utilize technology and data analytics tools to identify patterns and make more informed predictions. Regularly review and update forecasts to reflect changing conditions.

Supplier Performance Issues:

Problem:

Suppliers may fail to meet expectations regarding quality, delivery, or responsiveness.

Solution:

Establish clear performance metrics and key performance indicators (KPIs) for suppliers. Regularly evaluate and provide feedback to suppliers. Work collaboratively to address issues and implement corrective action plans. Consider financial incentives or penalties to motivate improved performance.

Compliance and Regulatory Challenges:

Problem:

Businesses must navigate an increasingly complex web of regulations, including environmental, labor, and ethical standards.

Solution:

Stay informed about applicable laws and regulations. Develop a supplier code of conduct and require suppliers to adhere to it. Conduct regular audits and assessments to ensure compliance and address any violations.

Best Practices for Excellence in Materials Purchase Cycle Management:

To achieve excellence in materials purchase cycle management, consider adopting the following best practices:

Centralize Procurement Functions:

Consolidate procurement activities under a centralized function or team. This promotes consistency, standardization, and economies of scale. A centralized approach also facilitates better data collection and analysis, enabling more informed decision-making.

Develop a Strong Supplier Qualification Process:

Implement a rigorous supplier qualification process to identify and select the most suitable suppliers. Evaluate potential suppliers based on a range of criteria, including financial stability, technical capabilities, quality systems, sustainability practices, and customer references.

Embrace Digital Transformation:

Leverage digital technologies and data analytics to transform your procurement processes. Automate repetitive tasks, use predictive analytics for forecasting, and utilize digital platforms for supplier collaboration and performance monitoring.

Prioritize Supplier Relationship Management:

Build and maintain strong relationships with key suppliers. Understand their business goals and challenges, and work collaboratively to achieve mutual benefits. Regular supplier reviews, joint problem-solving, and open communication are key aspects of a successful relationship.

Focus on Continuous Improvement:

Continuously seek opportunities to improve the materials purchase cycle. Encourage feedback from internal stakeholders and suppliers, and act on it. Measure and analyze key performance indicators (KPIs) to identify areas for enhancement and track the impact of process improvements.

Integrate Sustainability into Procurement Decisions:

Consider environmental, social, and governance (ESG) factors in your sourcing strategies. Evaluate suppliers’ sustainability practices and prioritize those who demonstrate a commitment to reducing their environmental impact and promoting social responsibility.

Develop a Skilled and Engaged Procurement Team:

Invest in training and development for your procurement team. Ensure they have the necessary skills and knowledge to excel in their roles. Foster a culture of engagement and empowerment, where team members are motivated to drive continuous improvement.

Utilize Data-Driven Sourcing Strategies:

Base sourcing decisions on data and analytics, rather than intuition or anecdotal evidence. Analyze spend data, market trends, and supplier performance metrics to identify cost-saving opportunities, negotiate better terms, and select the most suitable suppliers.

Monitor Market Dynamics and Trends:

Stay abreast of market dynamics and trends affecting your industry and supply base. This includes monitoring commodity prices, labor costs, technological advancements, and geopolitical events that could impact supply and demand.

Foster a Culture of Innovation:

Encourage innovation in your procurement processes and supplier relationships. Explore new technologies, business models, and collaborative approaches. Reward team members who propose and implement innovative solutions that drive value for the organization.

Conclusion:

An efficient and well-managed materials purchase cycle is critical to the success of any business that relies on physical goods. By optimizing each stage of the cycle, from identifying needs to evaluating supplier performance, businesses can achieve significant cost savings, improve production efficiency, and enhance overall operational effectiveness.

The strategies and best practices outlined in this article provide a framework for excellence in materials purchase cycle management. By embracing technology, fostering collaboration, prioritizing sustainability, and continuously seeking improvement, organizations can transform their procurement processes and gain a competitive edge in today’s dynamic business landscape.

Finally, it is important to recognize that the materials purchase cycle is an evolving and dynamic process. Businesses must remain agile and responsive to market changes, technological advancements, and shifting consumer demands. By adapting their procurement strategies and staying focused on continuous improvement, organizations can ensure a steady supply of materials, maintain efficient operations, and ultimately, drive long-term growth and success.

SUMMARY:

Materials Purchase Cycle

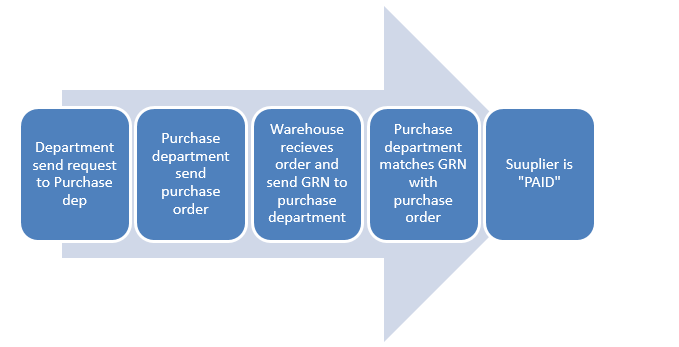

When a department stock level drops down , the particular department issues purchase request to purchase department in purchase requisition form stating stock item required with specific quantity and other specifications

On receipt of requisition form , purchase department place ORDER with supplier in purchase order form. This form contains all details regarding order specifications along with delivery dates and contract terms. Copies of this form is sent to supplier and warehouse

On receipt of specific order , the warehouse issues GOODS RECEIVED NOTE , stating specifications of goods received and date of goods received. Copy o GRN is sent to purchase department to match it against purchase order so that supplier can be paid to relevant supply of goods. After payment to supplier the purchase cycle comes to an end

Issue to Specific Departments

After purchase, materials are issued to particular departments on presentation of material requisition form, so that’s martials can be used in production of products. This form includes quantity issued to that department along with job number in which it is used. Other important forms include material transfer form(records transfer of materials from one department to other) and material return note(records any surplus inventory left after production process)